Bed of nails

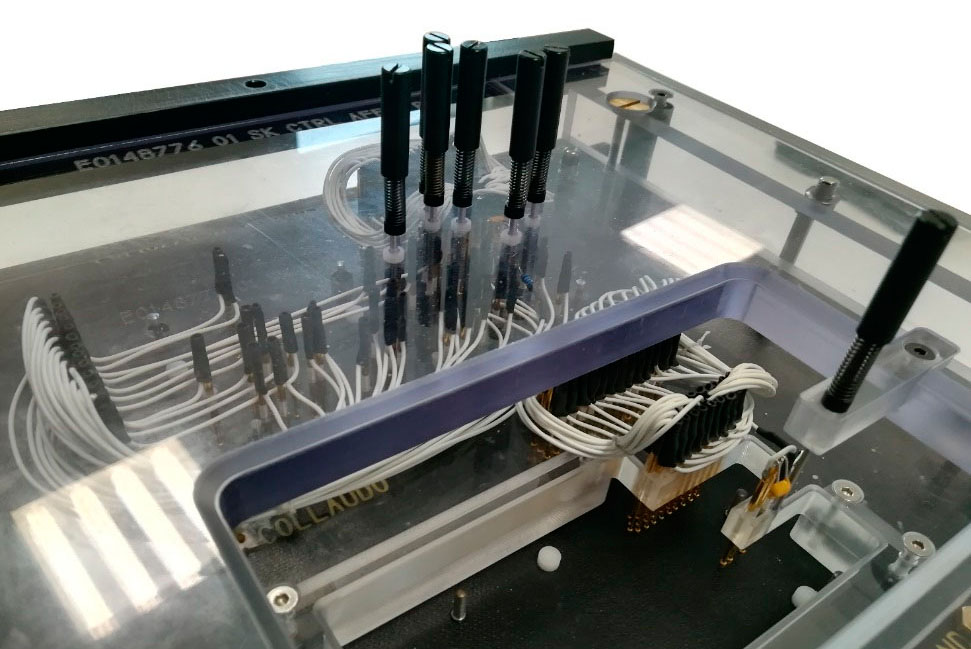

In this article we will see some examples of bed of nails made by CBL Electronics, suitable for specific boards. Here is the first example:

The object in the photo has been entirely studied in CBL according to the specifications of the board to test (hereafter UUT) provided by the customer. It is based on the use of our machine called Talia, which is used to test small/medium complexity boards functionally.

The Talia machine has these resources:

- 100 analog measurement lines (switchable through a relay matrix);

- 96 I/O digital lines;

- 4 programmable power supplies 0 – 20V

- Possibility to add other 4 programmable power supplies

- Multimeter 6.5 digit

Each bed of nails produced has an interface board towards the Talia which deals with the communication between the parties and manages the resources coming from it.

The design of the specific bed of nail for each UUT starts from the constructive files of the same to identify the board dimensions and the points of contact of the needles. Once identified, they are reported on the mechanical drawing program to realize all the standard parts that make up the bed and the specific part where to place the receptacles that contain the contacting needles.

These needles will then be wired either to the inside bed (assembled inside the bed) that allows us to distribute the stimulations that come from the Talia machine, or to a second connector that brings the analog measuring lines to the machine. Once the bed is made, it is connected to the Talia and through the SW, always our property, is written the whole test sequence to verify that the UUT is functioning on an electrical level.

Normally are realized two sections, one of test where inserted the board is run completely automatically and a repair where in this case the SW can be launched step by step and the operator can make measurements also manually, verifying any failures that may occur in the automatic testing phase. The repair section can also be used to repair boards that come back from the field.

Another example of a needle bed is shown in the figure below. In this specific case, giratrimmers have also been made and positioned to carry out calibrations during the automatic testing phase. In this case the test SW stops and waits until the operator performs the calibration and then continues to the next step once this has been done.

A further example of a specialised needle bed is shown below:

In this case we were able to contact some very small pitches (0.2 x 0.3 mm). Due to their proximity, it was necessary to carry out three automatic test areas: In this case the sw guides the operator of the UUT in the correct area and once the tests have been completed it stops and invites him to move the UUT to the next position.

For each test sequence a report is drawn up, identified by the bed connected to the machine, where all the measurements made on the single card are written.

Please leave some comments with your considerations, I will be happy to answer.

Stefano Moretti

- Log in to post comments